- ABOUT US

- Services

- Applications

- machine tools

- woodworking machinery

- marble working machinery

- wire drawing machines

- drilling systems

- lifting systems

- press bending sector

- earthmoving sector

- plant engineering sector

- energy sector

- railway sector

- shipbuilding sector

- truck-building sector

- building sector

- reduction units

- military sector

- airport sector

- wind energy sector

- recycling

- off-shore

- non-woven fabric

- press sector

- truck-building sector

- amusement parks

- packaging

- Quality

- Video

- News

- Contacts

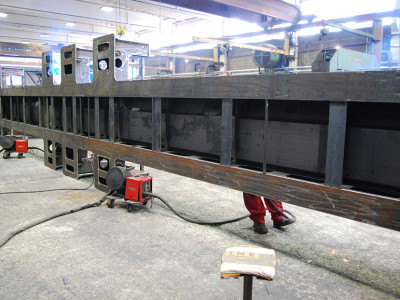

INDUSTRIAL METALWORK STRUCTURES

ITALIAN TALENT

GERMAN QUALITY

SLOVAKIAN PRODUCTION

SERVICES AVAILABLE

DEVELOPMENT AND DESIGN TECHNICAL DEPARTMENT

DEVELOPMENT AND DESIGN TECHNICAL DEPARTMENTBAMU reads, analyses and develops all kinds of technical drawings.

UNI EN ISO 9001 CERTIFICATION

UNI EN ISO 9001 CERTIFICATIONBAMU invests in its quality system: in 2011 it obtained ISO 9001 certification from TÜV SÜD, thus guaranteeing the quality of its products and its technological innovation.

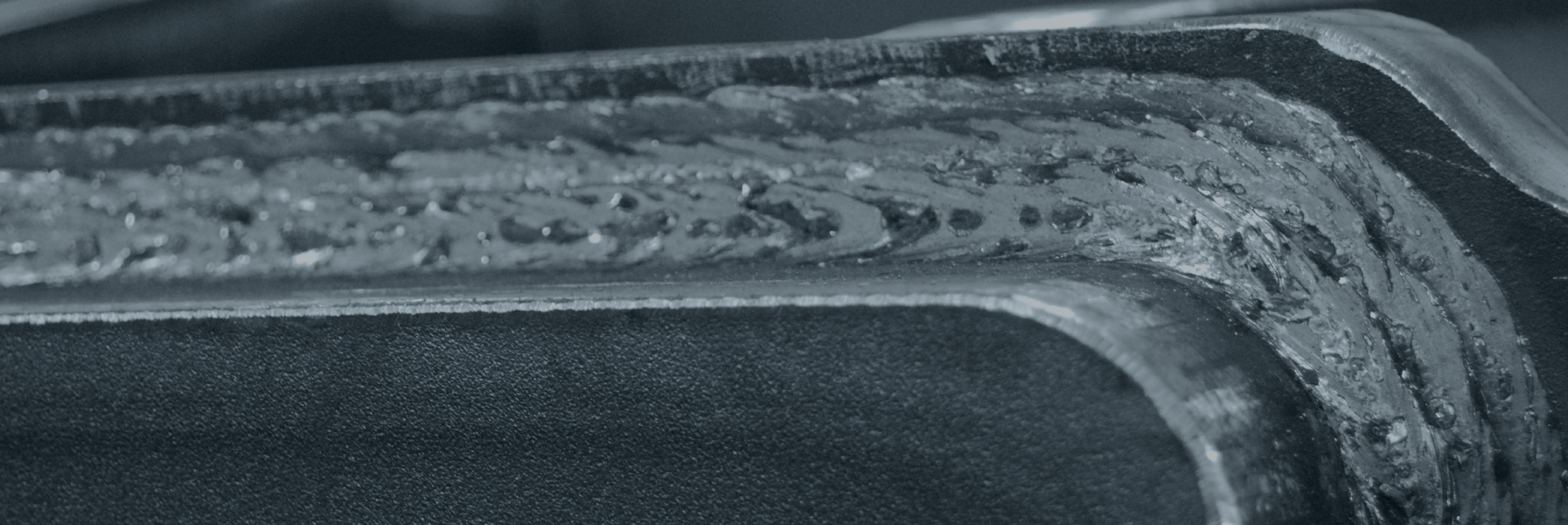

WELDING PROCESS CERTIFICATION

WELDING PROCESS CERTIFICATIONBAMU has its own welding processes and operators qualified according to the UNI EN 15614-1: 2005 and ASME IX standards.

MACHINING OPERATIONS

MACHINING OPERATIONSBAMU, in addition to metalwork structures, is able to supply machine-tooled finished products. In 2014 we bought a TOS drilling/boring machine for medium and large size pieces.

CUSTOMER SUPPORT

CUSTOMER SUPPORTThanks to the expertise acquired through years of experience, BAMU is able to offer the most suitable solutions for every stage of production, and for economic and manufacturing optimization.

PLANNING

PLANNINGBAMU plans all manufacturing phases to optimize results and ensure prompt delivery.

NON-DESTRUCTIVE TESTS

NON-DESTRUCTIVE TESTSBAMU performs non-destructive tests such as ultrasounds, magnetic particle and liquid penetrant according to the UNI EN 473 – ISO 9712 standard.

HEAT TREATMENTS

HEAT TREATMENTSBAMU offers stress relieving, normalizing and annealing services with standard or customized cycles.

SURFACE TREATMENTS

SURFACE TREATMENTSBAMU is able to provide final piece coating according to customer specifications.

News

-

We are happy to share with you that Bamu has obtained the UNI EN ISO... Read More

-

Team Tecnocarp with Confapi: together to fight coronavirus in Northern Italy

Companies are made of people. Team Tecnocarp and Confapi are proud to announce that Euro... Read More -

CML Innovations keeps growing!

CML INNOVATIONS’ new seat and assembling department CML Innovations is growing fast with the new... Read More -

Bamu at the Charity Christmas Bazaar in Bratislava

This year we have decided to wait for Christams in a different way -

Bamu present bending machine at MECSPE 2019

This year as well, Bamu with all Tecnocarp team> will participate in MECSPE 2019. Bamu will present its newest product: the bending machine... -

The new T “FERMAT WFC 10 CNC” machine

Bamu workshop is growing. A brand new boring and milling machine has been added to... Read More -

Great success at MECSPE 2018

Also the 17th edition of MECSPE, which it was held in Parma between 22nd and... Read More -

Tecnocarp Team at MIDEST 2018 in Paris

Tecnocarp Team will take part to MIDEST, a big European exhibition about industrial subcontracting with... Read More -

MECSPE 2018

Tecnocarp Team will take part to Mecspe with its five companies: Tecnocarp, Ares, CML Innovazioni,... Read More -

Bamu celebrates 10th year anniversary

2007-2017- during the last ten years Bamu grew up and developed to current size and... Read More -

New sand blasting and painting shop

Bamu is still growing and expanding In Bamu a brand new sand blasting shop and... Read More -

Tecnocarp Team great success at MECSPE 2017

The sixteenth Mecspe exhibition just ended. The show was running from March 23rd up to 25th and... Read More -

MECSPE 2017

BAMU sro will be at MECSPE 2017 – Technologies for Innovation, at the Parma Fairground from... Read More -

Tecnocarp Team is growing and expanding

Anticipating the market trend Tecnocarp has created a network specialized in heavy engineering. The main... Read More -

MECSPE 2016

BAMU sro will be at MECSPE 2016 – Technologies for Innovation, at the Parma Fairground... Read More -

New website now online

After extending its headquarters and its fleet of machines, BAMU has also renewed its presence... Read More -

Increasingly larger headquarters

BAMU grows. In October 2015 we inaugurated the expansion of the Valaská-Piesok facility in Slovakia:... Read More -

The Tecnocarp team

Thanks to the creative drive of Giuseppe Ballotta, five companies, each a leader in its... Read More -

New TOS milling/boring machine

In January 2015 BAMU machinery acquired an important addition: we did in fact install and... Read More

with 17.5 t capacity

Swinging-sliding turntable

Z axis with 2,200-metre stroke

Y axis with 3-metre stroke

X axis with 5-metre stroke

TOS milling/boring machining centre

MACHINING

with 17.5 t capacity

Swinging-sliding turntable

Z axis with 2,200-metre stroke

Y axis with 3-metre stroke

X axis with 5-metre stroke

TOS milling/boring machining centre

MACHINING

with 17.5 t capacity

Swinging-sliding turntable

Z axis with 2,200-metre stroke

Y axis with 3-metre stroke

X axis with 5-metre stroke

TOS milling/boring machining centre

MACHINING

BAMU CERTIFICATIONS

EN 1090-1:2009 +A1:2001

conformity of steel and aluminium structures

EN ISO 3834-2

quality for the fusion welding of metallic materials

EN ISO 9001:2009

production and technological innovation quality

EN 15085-2

quality of metal part welding processes

Applications

machine tools

machine tools woodworking machinery

woodworking machinery marble working machinery

marble working machinery wire drawing machines

wire drawing machines drilling systems

drilling systems lifting systems

lifting systems energy sector

energy sector railway sector

railway sector shipbuilding sector

shipbuilding sector truck-building sector

truck-building sector building sector

building sector reduction units

reduction units military sector

military sector airport sector

airport sector